3D Printing for interactive branding accelerated GTM and customization

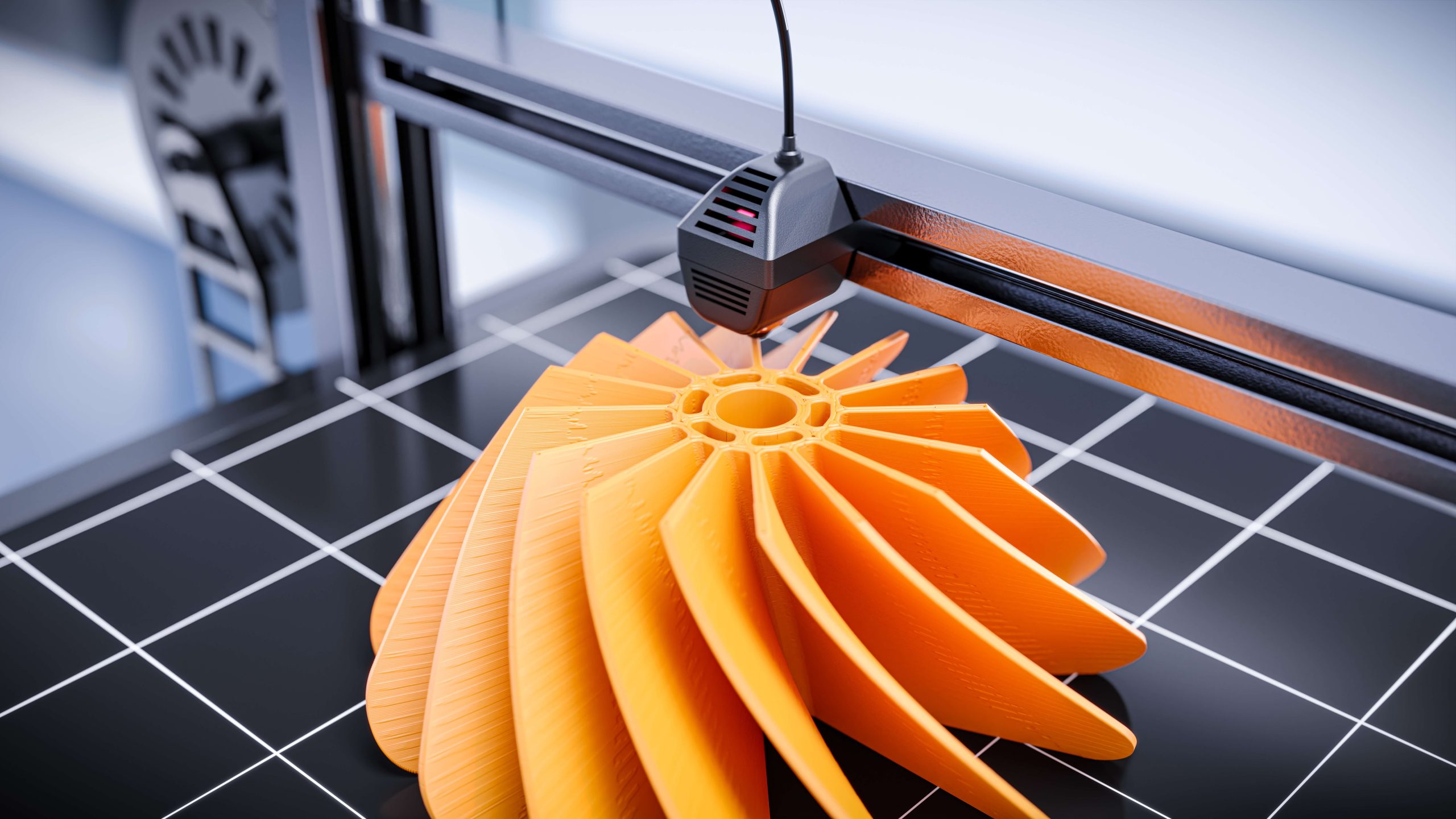

The idea of using a printer (typically associated with printing words or images on paper) to “manufacture” 3D objects might initially sound a little gimmicky. And indeed, there’s a world of 3D printers out there. Some (but not all) are aimed at the gimmick-loving audience—called hobbyists—or people who just want to have fun with 3D Printing.

Hobbyists print creative, crafty everyday objects like holders for various items, keychains, combs, bowls, and cutlery. This consumer audience is most noisily marketed to because they represent the bigger audience.

That’s why you’ve heard more about the gimmicky kind of 3D printers. But 3D Printing is far from a gimmick! Market leaders like BMW, Louis Vuitton, and Adidas have already employed 3D Printing for business benefits.

In this blog, we discuss proven business use cases for 3D Printing. We break down how 3D Printing can help you create an interactive brand experience and the overall role of 3D Printing in branding and marketing. We’ll also look at how 3D Printing enables faster go-to-market cycles.

How are hobbyist 3D printers distinct from industrial 3D printers? Which do you need for your business use cases?

The consumer audience typically buys the more affordable $100 to $500 type of 3D printer. As you can imagine, this is not going to work for business applications.

Hobbyist 3D printers are a far cry from the robust, high-capability printers that you would use for prototypes, components, and more. Industrial printers can run into thousands of dollars—you’re looking at spending anywhere from $20,000 to $100,000, depending on your needs. (Read on to understand the various applications for 3D printers).

The difference between hobbyist printers and industrial 3D printers can be compared to the difference between hobbyist and Instagram photographers who make do with camera phones and professional photographers who necessarily rely on DSLRs and other high-end professional cameras, not to mention a variety of lenses and other accessories.

Hobbyists and entry-level 3D printers work when aesthetics, rather than functionality, are a goal. They don’t work when you’re looking to make components that can withstand high pressure for industrial use or medical items that are sterilizable and biocompatible. In these cases, you need industrial FDM, SAF, and P3 printers, although some high-end Polyjet models may also qualify. Hobbyists, on the other hand, use Polyjet, SL and P3 printers.

Business Applications of 3D Printing

The use of 3D Printing for business and industrial applications is not new; it’s simply becoming more widespread and affordable today. BMW says it’s been using 3D Printing for vehicle parts and components since 1991! Louis Vuitton used 3D Printing in manufacturing almost seven years ago. The same goes for Adidas, which used 3D Printing to launch its Futurecraft shoes in 2017 (watch how they’re made here). Today, more and more brands are jumping on the bandwagon.

Let’s look at some ways that you can put 3D printers to use and examples from various sectors:

Footwear: 3D Printing for customization, personalization, and speed:

Brands are increasingly tapping into personalization as a means to forge deeper bonds with customers. Personalization is becoming a popular branding and marketing move, and 3D Printing can enable personalization-led branding and marketing by allowing for faster creation of personalized products. 3D Printing further enables the branding and marketing components for personalization by allowing customers to see products created right before their eyes.

Nike, in its “A.I.R. project” that aimed to “integrate the unique styles and athletic needs of 13 sponsored top athletes into individual shoe designs,” used 3D Printing (made even better with AI) to develop distinct prototypes for each athlete’s distinctive shoe. The brand showcased these earlier this year.

Other athletic shoe brands are not to be left behind when it comes to leveraging 3D Printing to make “futuristic” brand statements. Reebok launched a 3D-printed shoe in January last year, and Adidas also has a 3D shoe launch planned for later this year.

Auto and construction: 3D Printing for rapid prototyping and innovation:

Another great application for 3D Printing is prototyping. With 3D Printing, brands can release prototypes at an accelerated pace and test concepts quickly—-quicker innovation, quicker sign-offs from internal and regulatory stakeholders, and faster alterations in case the original prototype isn’t approved. All these add up to faster go-to-market timelines, which, for many brands, represents greater profitability.

Leading auto brands are already big on 3D prototyping.

At Volkswagen, for example, a “team” of seven 3D printers produces 93% of all previously externally manufactured tools in-house. Volkswagen Autoeuropa gained tool-development-linked cost savings of 91% and slashed development timelines by 95%. At this rate of cost savings and more rapid GTM, the brand earned back its investment in the tech.

Meanwhile, BMW has recently begun manufacturing production tools and aids using 3D Printing. These include customized orthoses for employees and commercial-size weight-optimized robot grippers utilized in entire floor assemblies. In fact, at BMW’s “Additive Manufacturing Campus” in Oberschleißheim, over 300,000 parts were 3D printed last year alone. That’s not all—over 100,000 printed parts are produced annually across all the plants that form BMW’s global production network, including facilities in Asia.

As if entire shop floors weren’t impressive enough, in Texas, a company is using 3D Printing for the construction of homes. (Yes, you read that right. Entire homes!). The 3D-printed homes are currently under construction and available for sale.

In fact, 3D Printing can play a big role in promoting affordable home design. UK-based For Everyday Life, for instance, builds affordable housing (under $99,000) using 3D Printing.

3D Printing for Interactive brand experiences:

3D Printing can transform how consumers interact with your brand. By leveraging 3D Printing in branding, you can create tangible, tactile experiences that resonate on a deeper level. One of the biggest advantages of 3D Printing is its ability to craft visually captivating and highly detailed items that leave a lasting impression. Whether it’s a miniature product model or a completely new design, using 3D Printing for marketing allows you to tell your brand’s story in a bold, unforgettable way (because your audience walks away with a tangible memento, a literal souvenir of the brand interaction in question).

Even if it’s something customers view rather than take away, 3D Printing creates an interactive brand experience that beats a screen-based experience. 3D models promote interactivity, enhancing the emotional connection with the brand. Imagine potential customers holding a model that brings your concept to life—the act of physically engaging with it makes your brand experience more immersive.

Another way to channel 3D Printing for marketing is to combine other technologies to drive improved brand storytelling. Imagine a consumer scanning a (QR code-fitted) 3D-printed object and getting transported into a digital universe (like a website or other portal), learning more about the brand or brand component and its story.

We can illustrate this with two examples from our stable of work here at magineu:

A fantastic instance of 3D printing promoting an interactive brand experience is the scale model of Tata Steel’s Jamshedpur factory, which acts as the centerpiece at the brand’s experience center. Besides being a stunning replica, the 3D-printed model also integrates projection mapping to animate and showcase the steel-making processes visually.

Another example of how we’ve channeled 3D printing into branding resides at the TCL digital experience zone. Here, we have created an immersive exhibit featuring an interactive table, 3D objects, and a floor-to-ceiling screen. Visitors engage with 3D objects on the table to trigger on-screen menus and select their viewing choices. People love it!

Events: 3D printing for branding and marketing

You can leverage 3D printing for brand marketing at events by creating custom, on-brand giveaways that make a lasting impression. Whether it’s small, personalized items or intricate designs that represent the brand’s identity, using 3D printing for brand swag bags solidifies your presence at an event.

Examples of 3D-printed branded giveaways include miniatures of a product, customized keychains, and wearable items. These can be 3D-printed on demand, giving the brand an immediate connection with the event audience (and creating a little buzz around your booth if you’re at an exhibition where it’s not easy to stand out among hundreds of your peers).

Why use 3D Printing in interactive brand experiences, prototyping, and more?

There are several reasons why 3D Printing is gaining traction for branding, manufacturing, and interactive brand experiences. These include:

- Speed: One of the greatest advantages of 3D Printing is the speed at which designs can be brought to life. Traditional manufacturing processes like molding and casting require extensive setup, whereas 3D Printing skips these steps, printing directly from CAD models.

- Sustainability: As brands push towards more sustainable practices, 3D Printing offers a way to minimize waste. Instead of cutting materials “from” as it is in most manufacturing processes, 3D printers use an additive process, creating less waste. Additionally, many 3D printing processes use eco-friendly materials, aligning with growing consumer demands for sustainability.

- Cost Savings: The ability to spot design flaws early, thanks to quick prototyping, leads to considerable cost savings and accelerates time-to-market, which in turn can boost profitability.

Considerations in 3d Printing: what info do you need before embarking on a 3d printing exercise?

When considering 3D Printing in marketing, branding, interactive brand experiences, and manufacturing, you need to ask key questions about the purpose of the printed item:

- Aesthetic-led considerations: If your 3D-printed models are meant for giveaways or enhancing interactive brand experiences, will they need to look realistic? Will the material need to support multiple colors or a smooth surface finish? Do you need rigid and flexible elements for dynamic designs?

- Functionality-led considerations: If the 3D-printed items will be used in demanding environments, do they need to withstand high temperatures, UV exposure, or chemicals? Will the parts require a long lifespan, or are they for one-time use only? Additionally, if you’re in the medical field, you’ll need to consider whether the parts must be biocompatible or sterilizable.

Conclusion

From interactive brand experiences to rapid prototyping and event merchandise, 3D Printing is driving efficiency to front and back-end processes. While it offers a wide range of benefits, like speed, sustainability, and cost-efficiency, there are also crucial considerations to make. Let us at magineu help conceptualize and create 3D-printed assets that align with your brand’s vision. With our experience and expertise, we’ll bring strategically calculated, ROI-focused 3D-printing-enabled branding, marketing, or manufacturing ideas to life. Contact us today—let’s brainstorm!